Reinforced mesh for concrete might not sound especially thrilling, but if you’ve ever walked on a cracked driveway, driven over a pothole-riddled car park or watched a patio slowly break down post-winter, you’ve seen what happens when concrete doesn’t quite have the back‑up it needs.

Concrete is highly effective at withstanding compressive forces, which is why it’s so reliable in supporting structures such as houses, bridges, and car parks. However, it’s pretty poor in holding tension, as when it’s pulled, bent or flexed, those internal stresses turn into cracks. That’s where reinforced mesh for concrete comes in.

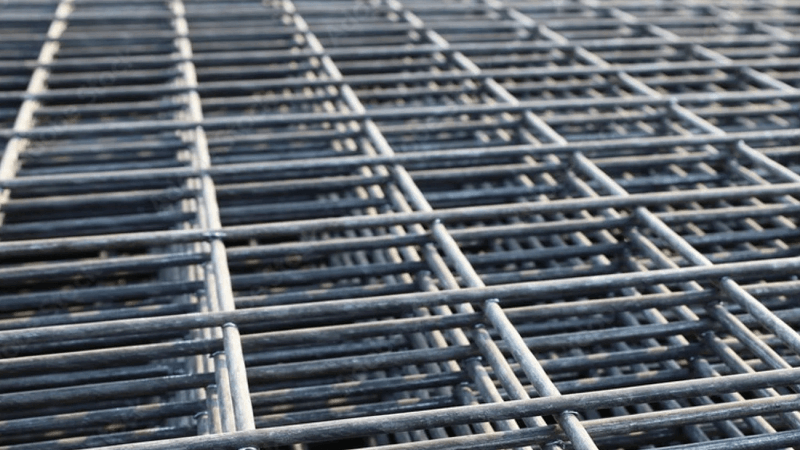

Instead of creating a standard slab and hoping for the best, builders place a lattice of steel bars, welded together into sheets, inside the pour. This reinforcing mesh takes on the tensile forces while the concrete deals with the compression, so the two materials work as a team. You still get some hairline cracking over time, but the mesh holds everything together and stops those cracks turning into big structural problems.

You’ll often hear people talk about A142 or A393 mesh. Those codes aren’t random: they relate to the bar size and spacing, and in turn the strength. A142 is a lighter mesh generally used for domestic work like garage slabs, garden paths and driveways with small cars. Step up to something like A252 or A393 and you’re into heavier‑duty territory, such as industrial floors, retaining walls or foundations that need to handle serious loads and traffic.

The mesh itself is usually made from carbon steel, manufactured to British Standards, so you get consistent quality and strength. Sheets commonly come in sizes like 2 m by 3.6 m, with longitudinal and cross bars welded at regular centres. That welded grid spreads loads evenly through the concrete, rather than letting stresses build up in one weak spot. Because it arrives pre‑fabricated, it’s quicker to put down compared with laying individual rebar bars one by one.

Placement is just as important as the mesh type. Stick it on the ground and pour concrete over the top and it’ll do very little. The mesh needs to sit properly within the slab, typically lifted on plastic or concrete spacers so there’s enough cover all round to protect the steel from moisture and, eventually, corrosion. For thinner slabs, that usually means closer to the bottom than the middle, so it can resist the tension that develops at the underside when the slab bends under load.

On bigger projects, you’ll see sheets lapped and tied together with wire so the reinforcement is continuous. The mesh shouldn’t be allowed to sag or get kicked out of position while the concrete is going in, otherwise you end up with bare patches and weaker areas. It’s the sort of detail that doesn’t look glamorous on site, but it makes a huge difference ten years down the line.

There are a few different flavours of mesh around now, too. Traditional steel is still the norm, but you can find alternatives such as basalt fibre mesh, which is lighter, non‑corrosive and can be supplied in large rolls. In some applications, it lets you reduce slab thickness and speed up installation, though it comes at a higher material cost and needs proper engineering design. Fibre‑reinforced concrete is another competitor: instead of a mesh, fibres are mixed straight into the concrete to control cracking. Sometimes it’s used instead of mesh, other times alongside it, depending on what the engineer specifies.

For homeowners, reinforced mesh for concrete crops up in more places than you might realise. That new driveway your neighbour’s had put in? There’s likely a light mesh in there if it’s been done properly. The slab under your garden office or extension, the floor in the garage, even the base for a hot tub or oil tank often relies on reinforcement mesh to cope with point loads and stop the surface spalling or dipping.

It also has a big say in how long something lasts in our weather. Between freeze‑thaw cycles, de‑icing salts, heavy rain and the odd heatwave, concrete in the UK goes through quite a lot. A well‑designed slab with the right mesh, correctly placed and properly covered, stands a much better chance of surviving those conditions without breaking up. Skimp on it, or throw it in at the wrong height, and you’re booking in future repair work.

Cost‑wise, mesh is one of those line items that’s relatively small compared with the overall job, but hugely expensive to fix if you get it wrong. It speeds up work for contractors too, as pre‑made sheets can be dropped, cut and tied quickly, rather than spending hours bending and wiring loose bars together on site. That’s part of the reason it’s become the standard choice for slabs and ground‑bearing concrete across the industry.

So while it might just look like a grid of metal to the untrained eye, reinforced mesh for concrete is doing the quiet, unglamorous work of stopping your patio from crumbling, your workshop floor from cracking under the car and your foundations from slowly tearing themselves apart. It’s one of those hidden details you never see again once the concrete goes off, but you’d definitely notice if it wasn’t there.